Change Language :

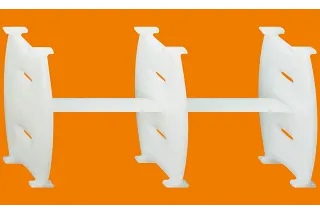

Crossbar and interior separation for the E6.1 6 and E6 series

New crossbar

Stronger and even less abrasion for greater cleanroom suitability

A new tribo-material makes it possible: the crossbars made from two-component injection moulding further reduce the abrasion of the E6 and E6.1 cleanroom chain.

The request came from a major customer in the semiconductor industry. Can the abrasion of the E6 cleanroom chain be reduced even further? The answer: yes - with a new, abrasion-optimised guide bar. And with a clever "division of labour" between the inner and outer materials.

Tech up

- Newly developed, cleanroom-compatible tribo-plastic

- igulen CR1 significantly reduces abrasion of the cables

- Easy to install and retrofit

- High ease of installation

Cost down

- Longer cable service life due to reduced jacket abrasion

- Quick to retrofit, an upgrade for greater cleanroom suitability

- Reduced maintenance effort

Proof

- igus igulen CR1 material generates 89% less abrasion

than the igus standard material*

Sustainability

- Saving resources through a long service life

- Have your energy or drag chain recycled at the end of its life cycle in the igus Chainge recycling programme. No matter which manufacturer. You will receive a voucher for this: Chainge recycling programme

*Measured and averaged on five different friction partners:

- CF340.250.01 2) CF270.UL.350.01.D 3) CF886.350.01 4) CAPE.A.10.0 5) CAPU.A10.0

Product range:

| Part No. | Suitable for: | Width |

|---|---|---|

| 2105.BBB.CR1 | Crossbar suitable for the E6.29/E61.29/E6.35/E61.35 ranges | 030 - 140mm |

| 225.BBB.CR1 | Crossbar suitable for series E6.40 / E61.40 / E6.52 / E61.52 | 040 - 300mm |

Available upon request

New interior separation

Further minimising abrasion

A new cleanroom material is used in the new interior separation of the E6 cleanroom chain. Sometimes it's the details that bring decisive improvements. A new interior separation further increases the abrasion resistance of the E6 and E6.1 cleanroom energy chain

Product range:

| Part No. | Suitable for | Width BBB |

|---|---|---|

| E6.29.1.CR1 | Separator suitable for the E6.29/E61.29 ranges | - |

| E6.35.1.CR1 | Separator suitable for series E6.29 / E61.35 | - |

| E6.40.1.CR1 | Separator suitable for series E6.29 / E61.40 | - |

| E6.52.1.CR1 | Separator suitable for series E6.29 / E61.52 | - |

| 2300.BBB.CR1 | Shelf suitable for all E6.20-52 ranges | 030 - 300mm |

Free white paper:

Energy supply for the cleanroom

In this white paper, you will learn how you can use the right energy supply in the cleanroom to

- Increase system efficiency

- Generate higher yields from production lines

- Use energy supply more sustainably

Suitable products

More information

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.