Change Language :

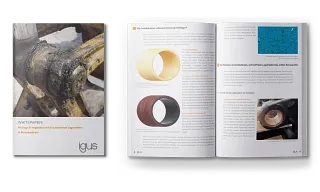

Heavy-duty disc harrow

This disc harrow works reliably when subjected to dirt and dust thanks to its liners and shafts.

It can be easily adjusted to any width. This means that rows of different widths in vineyards can be cultivated without time-consuming assembly. To do so, the tool rows are hydraulically shifted against each other. As the sliding bearing had to be maintenance-free, precise, space-saving, durable and very resilient, liners were fitted directly in the orifices of the machine frame. Shafts on which the respective row of discs is guided and fastened run in this guidance.

White paper: Important success factors for lubrication-free bearing points in construction machinery

- Reasons for switching to lubrication-free plain bearings

- Differentiation: Lubrication-free plain bearing vs. lubricated metallic bearings

- How self-lubricating plain bearings work

- What to bear in mind when switching to dry-running plain bearings

- and more.

▶Download PDF now

Merzbacher Metallbau, Peter Merzbacher, Großniedesheim, Germany

Consulting

I look forward to answering your questions

igus® Singapore Pte Ltd. Headquarter ASEAN+65 6487 1411Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.