Change Language :

Food-safe 3D printing with filament

Components that come into contact with food must not release any harmful substances, must be hygienically flawless and at the same time withstand mechanical loads. 3D printing with food-safe filaments from igus makes it possible to manufacture such components economically and quickly, from simple bearings to complex grippers or guide elements in packaging machines.

Food-compliant materials such as the iglidur filaments i150, i151 and A350 fulfil the requirements of the FDA and/or EU Regulation 10/2011. They are not only approved for direct food contact, but are also particularly temperature-resistant and many times more wear-resistant than PLA or ABS. The characteristic blue colouring makes any abrasion or even fragments immediately visible and detectable - an important safety aspect in production. This page provides an overview of important industry standards such as HACCP and EHEDG, shows typical areas of application, and gives advice on material selection and processing.

When is a filament food-safe?

The term "food-safe" means that a material can be used safely with food without releasing harmful substances or jeopardising its purity. This is particularly important in the food and packaging industry, where hygiene plays a central role.

For a filament to be considered food-safe, it must fulfil strict requirements such as EU Regulation 10/2011 and FDA standards.

Food-safe certificates prove that materials are suitable for direct food contact and hygienically sensitive production processes.

This is what you will find on this page:

Food-safe 3D printing: Advantages and significance for the industry

Safe food contact: The certified materials from igus (e.g. in accordance with EU 10/2011 or FDA) prevent the migration of harmful substances and guarantee product safety.

Hygienic processing: The FDM process creates smooth, sealable surfaces that prevent bacterial growth.

Customised machine components and tools: 3D printing with food-safe filaments delivers customised components with complex geometries for machines and applications.

Cost-effectiveness & fast prototypes: Prototypes, spare parts or special components are created cost-efficiently and quickly using 3D printing - without long delivery times or expensive tools.

Sustainability & material efficiency: Components are only printed when they are actually needed. This saves material, reduces waste and makes warehousing superfluous.

Where are food-safe filaments used?

Components made from food-safe filaments are used in the food processing industry, in packaging technology and in bottling plants, among others. Food-safe components from 3D printing can also play a decisive role in the following areas of application:

Packaging machines

Learn morelocal_shipping

Transport and conveyor systems

Learn moreprecision_manufacturing

Production components

Learn more

Precise product turners from 3D printing

In conveyor belt systems for beverage or cosmetics filling, products such as beverage cans must be precisely positioned or turned at high speeds. A key element here can be a product turner customised to the size of the can. However, conventional solutions made of bent steel wires or milled material blocks involve high production costs, material waste and long delivery times.

With the wear-resistant iglidur i150 filament, igus offers a cost-effective and fast alternative in FDM 3D printing. The components are wear-resistant, can be produced without tools and can be quickly adapted to different can formats and installation situations. The optimised design with a spiral-shaped inner structure ensures controlled turning of up to 60,000 cans per minute, while integrated maintenance openings simplify cleaning. This significantly increases flexibility, productivity and resource efficiency in filling technology.

Wear-resistant, food-safe filaments from igus

The igus range offers suitable solutions for different applications in practice. Food-safe filaments from igus are certified in accordance with the requirements of the FDA and/or EU Regulation 10/2011. Discover the filament that suits your application.

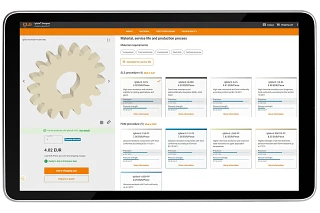

3D printing service with food-safe filaments

Do you need a food-safe component for your application but don't have a 3D printer available? Our 3D printing service provides you with components made from our in-house, wear-resistant iglidur plastics. Our specially developed materials are ideal for applications in direct or indirect food contact and offer up to 50 times greater wear resistance than regular 3D printing plastics**.**

Just upload the CAD model of your component online and let us take care of its production in the desired quantity. You can also use our service life calculator to calculate the expected service life of each individual component online.

Requirements and standards for food-safe filaments

verified

What certificates are available?

Safety in food production is regulated by strict legal requirements to ensure hygiene, quality and product safety. EU Regulation 10/2011 and FDA certification are particularly relevant for food-safe filaments. They set definitions and limits for safe use in direct contact with food. Specific hygiene guidelines, such as the HACCP concept (Hazard Analysis and Critical Control Points), as well as hygiene standards, such as those of the EHEDG (European Hygienic Engineering and Design Group), also play an important role. igus offers food-safe filaments specifically for these requirements.

euro

EU Regulation 10/2011

EU Regulation 10/2011 is the central European standard for the regulation of materials that come into contact with food. This food-safe certificate includes

- migration limits: The regulation sets strict limits on the maximum amount of substances that may migrate from a material into the food.

- Material testing and documentation: Manufacturers must provide comprehensive documentation on the composition and safety of the materials.

- Traceability: To ensure transparency throughout the entire supply chain, every stage of material processing must be fully documented.

place

FDA certification

The Food and Drug Administration (FDA) analyses the chemical properties of materials with regard to specific food groups, such as fatty, alcoholic or highly acidic products.

In order to obtain authorisation, manufacturers must prove that no harmful substances migrate into the food. This is done through migration tests with different food groups. The aim is to guarantee product safety under realistic conditions and ensure compliance with strict limit values.

clean_hands

Hygiene guidelines: HACCP and EHEDG

The HACCP concept is a legally regulated self-monitoring system for food companies that ensures food safety and protects consumers. It comprises key components such as incoming goods inspection, temperature monitoring, cleaning and disinfection, pest control, traceability and staff training. The aim is to guide companies towards the systematic and hygienic handling of food.

Hygienic design according to EHEDG is an internationally recognised concept for the design of production facilities with food contact, which aims to prevent contamination through measures such as smooth surfaces, suitable materials and easy-to-clean geometries. It is based on EU regulations and EHEDG guidelines that regulate materials, surfaces and geometries so that equipment is easy to clean and hygienically safe. The aim is to improve food safety while making cleaning processes more efficient.

Tips for processing food-safe filaments

The material should be stored in a dry place and protected from environmental influences. It should also be removed from the packaging in a dust-free environment and dried before printing. Drying prevents the moisture contained in the filament from degrading the material when it melts in the nozzle and prevents air pockets from forming. This ensures that the surface finish and quality remain the same. Tips on filament drying can be found in the processing instructions on the individual product pages in the igus filament shop. A good rule of thumb is a drying temperature that does not exceed the maximum application temperature of the plastic, but also does not damage the plastic spool. It is easy to dry the filament in a standard household convection oven, and also in a specially designed dry air oven.

Regular maintenance and cleaning of the printer is essential to ensure that the 3D printing filament can be processed without any problems. All parts that come into contact with the filament should be free of residue. This is particularly important for the extruder pinion and the print nozzle. The manufacturer of desktop 3D printers Ultimaker provides some cleaning routines for its devices that can also be used on other devices. In addition to the pinion and nozzle, a clean print bed is also essential; we recommend a clean glass plate. Adhesives should not be used unless a food-safe adhesive is available.

To achieve optimum results when 3D printing food-safe components, the print settings in the slicing software (e.g. Bambu Studio, Orca Slicer or Ultimaker Cura) should be selected in such a way that the surface of the object is as dense as possible. To achieve this, we recommend reducing the printing speed and adjusting the line width to the nozzle diameter. This can reduce unevenness in the component surface and gaps in the cover layers. The material must also be protected from dust before and during printing, which is why a printer with a closed build chamber is advisable.

We recommend that food-compliant components are not produced in multi-material printing together with other, non-food-compliant materials, as mixing of the materials cannot be completely ruled out. Accordingly, the support material should also either be food-compliant or the same material should be used as the support material.

The information on this page contains tips on 3D printing of food-safe plastic components, but does not replace the necessary knowledge on the part of the user as to which food conformity requirements exist in the specific application. Depending on the application and requirements, tests on the specific component may also be necessary. It is also recommended that the declaration of conformity is checked carefully for the application, as there are major differences in the food sector with regard to permitted temperatures and the permitted contact duration.

To optimise the processing of igus filaments, we provide our customers with preset configurations in the form of free print profiles for download, which are specially adapted to common 3D printers such as Bambu Lab, Prusa and Ultimaker. Simply import them into the slicing software and start printing.

To the overview of filament printing profilesMore about 3D printing at igus

Sample box

See our materials for yourself and order a sample box with various 3D-printed parts.

Printing profiles

For optimum processing of igus filaments, we offer the material profiles for common printer models free of charge for download.

3D printing tips

No more stringing, warping and spaghetti: With our 24 tips, you can easily avoid the most common problems in filament printing.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.