Change Language :

igus products without PTFE

As a manufacturer of industrial components made from high-performance polymers, we use a wide variety of materials. PTFE, for example, ensures low-friction dry operation and makes the use of lubricants superfluous. Thanks to the superordinate PFAS, some of our plastics become more robust and more resistant to wear, weathering, chemicals and extreme temperatures. However, PTFE and PFAS are considered "forever chemicals", as both are difficult to degrade in the environment and have a long service life. Substances of this type can be harmful to the environment, humans and animals, which is why the EU is currently looking into regulating or banning PFAS.

However, our development department has been working on alternatives to PTFE for some time now. Thanks to new formulations, extensive testing and adapted production processes, we now have a wide range of materials and products in our portfolio that do not contain PTFE - such as the material iglidur JPF, which was named Product of the Year 2025 by Kunststoff Magazin. We are still carrying out research to find suitable substitutes for materials with PTFE. Below we present our solutions and provide you with further details and background information on these materials and our products.

The most important facts in brief

- Depending on the PTFE content, plastic products may be affected by a possible PFAS ban.

- A wide range of igus materials do not contain PTFE, and no traces of the critical PFAS substances have been detected in other igus materials*.

- If PTFE is not banned, igus materials are generally not affected.

igus materials without PTFE and tested for harmful PFAS

The following igus materials do not contain PTFE and are therefore not affected by future PFAS regulations.They were also tested for the 96 PFAS substances considered critical for the environment and health according to the SQP M1227 test method (LC-MS/MS and GC-MS) and do not contain any substances >0.1 per cent by mass. Excluded are substances from the group of fluoropolymers, which are not tested for. A complete overview of our materials can be found here.

Our PTFE-free material iglidur JPF was honoured by Kunststoff Magazin as Product of the Year 2025 in the materials category.

iglidur materials without PTFE and tested for harmful PFAS

igumid materials without PTFE and tested for harmful PFAS

xirodur materials without PTFE and tested for harmful PFAS

PTFE-free plain bearings tested for harmful PFAS

iglidur plastic bearings make maintenance-free bearing points possible without PTFE and are tested for the 96 PFAS substances considered critical for the environment and health. They are durable, require no additional lubricants and reduce friction.

PTFE-free linear technology tested for harmful PFAS

drylin linear technology from igus is PTFE-free and also tested for the 96 critical PFAS substances. Our linear technology offers maintenance-free, quiet and precise movements. It is ideal for applications that require high reliability and durability.

PTFE-free chainflex cables from igus

chainflex cables from igus are PTFE-free and very flexible and durable. They are ideal for moving applications and guarantee a long service life without harmful substances. They are perfect for applications that require strong and durable cables.

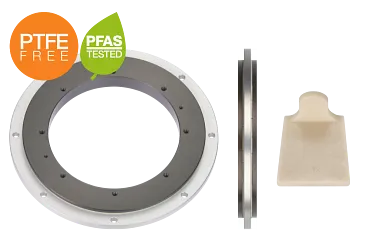

xiros ball bearing: PTFE-free, lubrication-free and maintenance-free

The xiros ball bearing range includes around 30 PTFE-free products that have also been tested for harmful PFAS substances. The xirodur B180 material is characterised by a long service life, low wear values and good chemical resistance.

PTFE-free and harmful PFAS tested gears

Our iglidur plastic gears enable maintenance-free applications without PTFE and have been tested for 96 PFAS classified as critical to the environment and health. They are durable, require no additional lubricants and minimise friction.

PTFE-free iglidur PRT slewing ring bearings

The sliding elements of the iglidur PRT slewing ring bearings are demonstrably PTFE-free and tested for critical PFAS substances. They are tested for load and wear in the igus laboratory, operate environmentally friendly in dry operation and are 100% lubrication-free.

PTFE-free bar stock tested for harmful PFAS

iglidur bar stock enables the production of maintenance-free, PTFE-free sliding and wear-resistant parts. They are tested for the 96 PFAS substances considered critical, are self-lubricating and are characterised by low coefficient of friction and extreme wear resistance.

PTFE-free designing with igubal spherical bearings

All combinations of igumid G housing with iglidur J3 or iglidur R shown in the shop, whether as spherical insert bearing or spherical ball, are PTFE-free. The range does not cover all possible variants, but all standard products can also be manufactured PTFE-free.

Note: The presence of ubiquitous traces of undesirable substances can never be excluded. As igus has no influence on the use of the above-mentioned materials and products, we assume no guarantee or liability, either expressly or implicitly, in connection with the use of this information.

With in-house development and own test laboratory for PTFE and PFAS alternatives

We have a very high level of vertical integration. Among other things, we operate our own Development Department for materials, an in-house Compounding Department, a Technical Centre for process engineering tests and an extensive test laboratory for materials and products. On this basis, we have developed possible alternatives to PTFE and PFAS that are no more expensive and do not contain any problematic ingredients that could lead to a future ban. We have tested these alternatives in our test laboratory under real conditions for the changed material compositions and their possible effects on material specifications.

The results speak for themselves: materials with substituted PTFE show significantly better performance in terms of friction and wear behaviour compared to the original materials containing PTFE. The new PTFE substitution reduces wear rates, which were good to start off with, by an average of approx. 60%. Thanks to the clever design of the formulations, the other material specifications - temperature stability, mechanical load-bearing capacity and shrinkage behaviour - remain almost identical. With our new formulations, extensive testing and adapted production processes, we can offer you a wide range of PTFE-free and PFAS-tested materials and products.

From the development department: Major progress with PFAS and PTFE

How far has igus progressed with the topic of PFAS and PTFE?

Magnus Orth: "We are continuing to develop PTFE-free alternatives to our most successful PTFE-containing materials at full speed. The main focus is on expanding our top five plain bearing materials to include variants without the fluorine-containing additive. The aim is for the PTFE-free versions to have the same or better specifications than the PTFE-containing originals. In 2024, we already introduced the materials iglidur JPF and iglidur WPF. These are PTFE-free versions of the very versatile and proven iglidur J, as well as iglidur W300, which is optimised primarily for somewhat higher loads and wear requirements. We have also developed a formulation for a PTFE-free iglidur F. Now, just in time for Hannover Messe 2025, we can announce a major breakthrough. We have finalised PTFE-free versions of the most successful iglidur material - iglidur G - and we can now also offer the high-temperature standard iglidur X in the PTFE-free version. We also offer iglidur HPF, a variant specifically for use in liquid media."

What was the biggest challenge during development?

Magnus Orth: "Especially for the widely used iglidur materials, it is very difficult to ensure that the products offer the same performance in practice as the PTFE-containing versions. As these are used in an extremely wide range of applications with very different requirement profiles and the design of plain bearings - if it is to be truly accurate - is based on a great deal of experience and empiricism and is difficult to simulate theoretically due to the many influencing factors, the testing effort is considerable. Our well-equipped wear laboratory and our experience help us with this. PTFE really comes into its own when it comes to chemicals and temperature-resistant bearings. It is not easy to find materials with similar specifications. Nevertheless, we have succeeded."

Which applications or users in particular benefit from the new PTFE-free plain bearing materials?

Magnus Orth: "The range is wide. Many manufacturers are currently looking for products that work without PTFE or even completely without PFAS. In addition to these aspects, resistance to corrosive cleaning agents or high temperatures are also important in food processing. In the automotive sector, meanwhile, there is particularly high price pressure and in consumer products such as electrical appliances and the like, many other factors often play a role. With now almost 30 plain bearing materials without PTFE and over 40 materials in which we can already exclude the 100 PFAS that are considered critical, we offer a wide range of solutions here."

PFAS in focus: planned restrictions, challenges and solutions

What exactly are PFAS, why are they so popular in industry and the consumer sector? Why is there a threat of an EU-wide ban and what can companies do now?

The white paper sheds light on these questions and shows how igus, as a plastics processor, is responding to the planned restriction at an early stage and can offer its customers PTFE-free and PFAS-tested alternatives.

Background information on PFAS

What is PFAS?

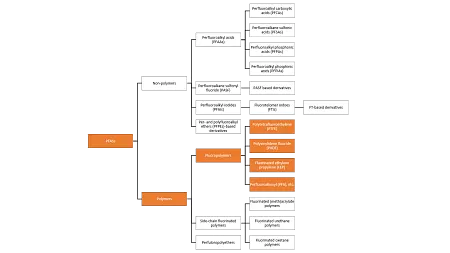

Per- and polyfluorinated alkyl substances (PFAS) are industrial chemicals that are used in numerous industrial processes and consumer products due to their special technical specifications. They can be gaseous, liquid or solid and consist mainly of carbon and fluorine atoms. Apart from this, PFAS molecules can have completely different structures, which means that they can have many different specifications. As a group of substances, PFAS comprise many different compounds: More than 4,700 according to the OECD database, more than 9,000 according to the EPA and even more than 10,000 according to the EU Commission, indicating that it is neither a unique nor a constant value - it is mostly based on estimates. With PFAS, a distinction is made between non-polymers and polymers, which in turn are subdivided into further substance groups:

- Non-polymers: In the subgroup of non-polymers, the compounds perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) are the best studied. Like many PFAS, these two compounds are also difficult to break down and are now detectable in the environment, in the food chain and in humans. PFOA and PFOS have a proven negative impact on health. Together with PFHxs and PFNA, they account for 90% of the current PFAS load.

- Polymers: The subgroup of polymers includes fluoropolymers. Fluoropolymers consist of a carbon chain with directly attached fluorine atoms. This makes them so strong that they cannot decompose into toxic substances. The only danger is the possible use of toxic additives during production in the form of emulsifiers. Fluoropolymers are used, for example, in coatings, seals and cable insulation. Fluoropolymers include polytetrafluoroethylene (PTFE) among other substances.

Current legal situation regarding PFAS (date: 25/09/2025)

EU: The use of PFOS has been largely banned since 2006 and that of PFOA since July 2020 - you can find our confirmation here. ECHA plans to discuss a draft opinion on PFAS in spring 2026 (ECHA/NR/25/28). The European Chemicals Agency intends to deliberate on the draft opinion of its Socio-Economic Analysis Committee (SEAC) regarding the proposed EU-wide restriction of per- and polyfluoroalkyl substances (PFAS) after the Committee's meeting in March 2026. The SEAC's draft opinion on the PFAS restriction proposal will contain the assessment of the socio-economic aspects, including the availability of alternative substances and technologies. SEAC plans to adopt its draft opinion at its meeting tentatively scheduled for the first half of March 2026. The consultation will start shortly after this meeting and will remain open for 60 days, during which stakeholders can provide feedback. You can find more information on PFAS here at ECHA.

USA: The EPA has issued a final rule adding five PFAS substances to the list of over 170 PFAS substances. These are reportable under the Toxics Release Inventory (TRI), a centralised database for public reporting of chemicals. Fluoropolymers are not included in the TRI list. You can also find out more about PFAS directly at the EPA here.

*The products were tested for the 96 PFAS substances considered critical for environment and health according to the SQP M1227 test method (LC-MS/MS and GC-MS) and do not contain any substances >0.1% by mass. Substances from the group of fluoropolymers are excluded as products are not tested for them.