Change Language :

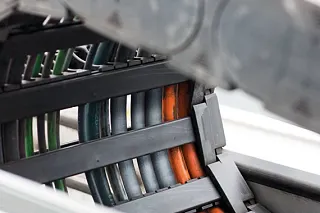

Glide pads for energy chains on long travels

Friction- and wear-optimised sliding elements and rol e-chains extend the service life of igus energy chain in gliding operation

A few years ago, igus developed glide shoes for gliding energy chain applications. These can significantly extend the service life of energy chain systems. This solution is recommended for travel speeds between 1m/s and 3m/s.

- Wear protection for the energy chain

- Especially for gliding applications in environments with abrasive media

- Easy handling

Product range

Available from stock/*Available from May 2021/ ***Available from autumn 2021

| Part No. glide pad | For series | Part No. fixed end adapter |

|---|---|---|

| GSC.E4Q.58** | E4Q.58 | GSC.FP.56/58.SLS** |

| GSC.E4.56* | E4.56 | GSC.FP.56/58.SLS** |

| GSC.E4Q.44*** | E4Q.44 | GSC.FP.42/44.SLS** |

| GSC.E4.42* | E4.42 | GSC.FP.42/44.SLS** |

| GSCE4Q.34*** | E4Q.34 | GSC.FP.32/34.SLS** |

| GSC28* | GSC28 | GSC.FP.32/34.SLS** |

Tech up

Cost down

Proof

Sustainability

Gliding or rolling

Glide shoes for energy chains versus roller energy chains

igus glide shoes for energy chains are characterised as an economical alternative to rol e-chains for the lower speed range between approx. 1m/s and approx. 3m/s.

Standard applications are equipped with e-chain gliding without glide shoes or rollers. If such e-chains applications are equipped with glide shoes, the service life expectancy can be increased. Depending on the application, a doubling of the service life can be achieved with igus glide shoes. In comparison, a rol e-chain generally quadruples the service life expectancy. The rol e-chains are the right and first choice for highly dynamic systems with speeds of 3m/s and higher.

Glide shoes will not be able to provide the desired benefit in such systems, as even gliding shoes with the best material composition will reach their limits.

For systems that run highly dynamically and have to cope with high cable loads, there is no alternative to roller energy chains.

Tested

Friction down - Service life up

For over 50 years, igus has been developing plastic compounds for the manufacture of plain bearings and plastic energy chains. The aim of material development is to find materials that bring cost down and tech up. An important factor is the longevity of gliding plastic energy chains. From the very beginning, highly abrasion-resistant materials were used to manufacture the e-chains. Roller energy chains were introduced just over 20 years ago and are constantly being developed further.

In comparison

igus glide shoe for energy chains vs. competition glide shoes

Product range variety

Suitable and recommended igus energy chains

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.