After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

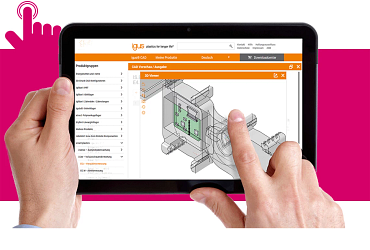

Since the i.Sense Wonderbox is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

This free white paper explains: