After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

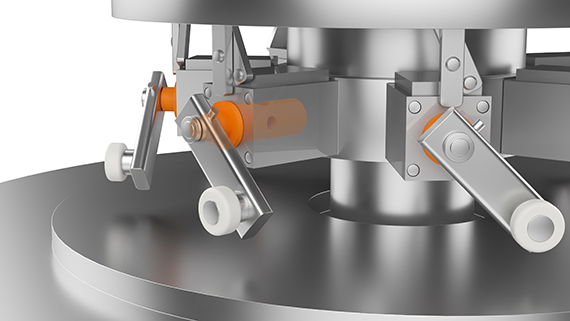

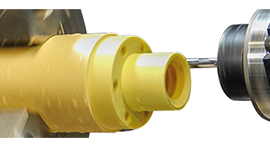

made of lubrication-free plastics

We check the feasibility of your request. If everything is OK, we will send you a binding offer. If you have ordered directly, production will be approved immediately.

After your order, we start with the CNC processing of your individual milled and turned parts. Receive them either by delivery or pickup.

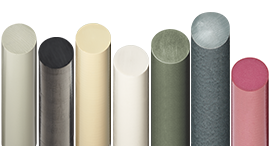

A large number of different iglidur® high-performance polymers are available to you. The ideal iglidur® material can be found for almost every application, from high temperatures to sea water, from food to automotive. Various online tools and our experts are at your disposal for the selection of materials.

If things have to go faster: select our express option and your components will be ready to ship in 3 days.

✓ ISO 2768-m/K applies to the general tolerances of the parts with regard to length, shape and position

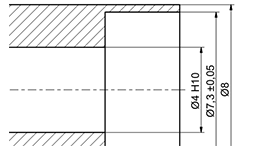

✓ The following minimum tolerance widths (see DIN ISO 286) must be taken into account for deviating special tolerances (for linear dimensions) and for fits:

✓ Holes and bores can be configured as ISO metric thread (M) ✓ The surface roughness corresponds to the typical, expected qualities of finished surfaces (minimum expected: Ra = 2-3µm)

These standards are to your advantage: We can calculate the prices automatically and your order can be processed more quickly. You save valuable time.

Requirements above and beyond our manufacturing standards are possible, provided that a prior feasibility check confirms this. The automatically calculated price will then be adjusted if necessary after the individual check.

To ask for different requirements, you can click on "Ask for help" in step 2. Alternatively, you can simply upload your technical drawing with the different requirements in step 3 and point out the different requirements to us in the last step of the tool.

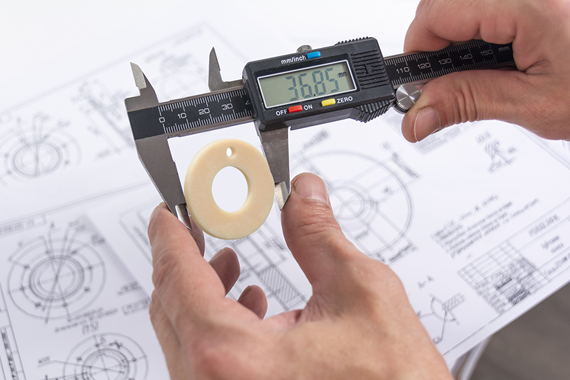

You receive dimensionally accurate components with tightly toleranced dimensions and fits. Narrow tolerance ranges (up to tolerance grade 9 acc. DIN ISO 286) are usually feasible. Tolerance widths of 0.05mm are therefore not a problem.