Change Language :

Streamline your production with ready-to-install readychain® energy supply systems

readychain® complete systems in use - our highlights

All you need to know about readychain® energy chain system

what are the benefits of choosing readychain®?

For the production of machines and equipment, there are many good reasons to decide in favour of ready-to-install energy chains:

- Harnessing time is reduced by up to 95%

- Reduction in manufacturing costs

- Minimal amount of logistics work - no storage space necessary

- Procurement optimisation - one system, one part number

- Reduced assembly time - less machine downtime

- On-site installation - international service with 31 subsidiaries

- Special designs are possible - igus is developing further components

Frequently asked questions

readychain® energy chain versions

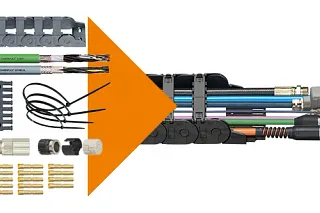

A readychain® system consists of many components: energy chain, highly flexible cables, connectors, metal sheets, mounting frames ... Discover the four standardised versions of our readychain® systems here. Everything from one source, everything from your system supplier and even with a guarantee!

Basic

Consists of an energy chain equipped with electric cables, pneumatic and hydraulic systems without plug connections.

Your benefits at a glance

BASIC

Assembly time reduction

■■□□□

Reduction of logistics effort

■■■□□

Procurement optimisation

■■■□□

igus® Singapore

Supplier & distributor of readychain® harnessed energy energy chain system in Singapore.

84 Genting Lane

#06-03 Axxel Innovation Centre

Singapore 349584

Standard

Consists of an energy chain equipped with electric cables, pneumatic, hydraulic and sensor systems including plug connections.

Your benefits at a glance

STANDARD

Assembly time reduction

■■■□□

Reduction of logistics effort

■■■■□

Procurement optimisation

■■■■■

Standard plus

Consists of an energy chain equipped with electric cables, pneumatic, hydraulic and sensor systems including plug connections as well as mounting plates for fixation.

Your benefits at a glance

STANDARD PLUS

Assembly time reduction

■■■■□

Reduction of logistics effort

■■■■■

Procurement optimisation

■■■■■

Premium

Consists of an energy chain equipped with electrical cables, pneumatic and hydraulic hoses and sensor systems including connectors as well as transport and assembly rack.

Your benefits at a glance

PREMIUM

Assembly time reduction

■■■■■

Reduction of logistics effort

■■■■□

Procurement optimisation

■■■■■

**

All components in one - with guarantee

**

Energy chains from igus are already being reliably used in hundreds of thousands of applications all over the world. From beverage machines up to steelworks, from simple linear applications up to the most complicated task - igus offers thousands of installation options.

With more than 1,350 chainflex cables from stock, igus offers the largest range of cables specifically for energy chains. Thanks to the industry's largest test laboratory, igus is the only supplier in the market able to offer a 4-year guarantee on all chainflex cables.

All standard plug-in connections and more than 6,000 drive cables suitable for 34 manufacturer standards are available. In addition, the modern sensor systems from smart plastics for intelligent condition monitoring and predictive maintenance can be integrated directly into the ready-to-install energy supply.

Further information

igus readychain factory

- 1,600 harnessed energy chain systems leave the factory every week

- 4,175m² for harnessing

- 4,150 employees worldwide, including 359 employees who perform harnessing work

- 35 igus subsidiaries worldwide including 14 readychain factories

The largest test lab worldwide

From more than 15,000 tests performed per year, we have created what is probably the world's largest test database. This database gives us the ability to always select the right product for your specific application. Individual tests for your industry are also possible.