Change Language :

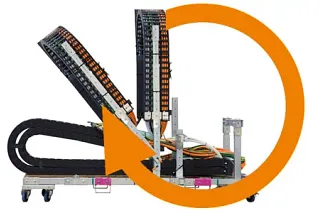

The assembly transport rack for ready-to-install energy supplies

The readychain rack is a customised rack made of a modular system that facilitates the transport and assembly of a harnessed energy supply system. To get it to the machine quickly and safely, igus has developed a telescopic transport rack in a modular design. It can be adapted to the interface of the respective machine with millimetre precision within one working day.

In mechanical and plant engineering, the process costs in the prototype phase are reduced by up to 80%. This comparatively cost-effective concept pays for itself from a production run of just a few machines per year, allowing you to utilise the advantages of the modular rack even for small volumes.

Frequently asked questions

Good reasons for using the readychain® rack

Save up to 80% process costs during prototyping

- Modular supports and braces for a perfect fit

- Telescopic: Length adjustment possible at any time

- Indexing mechanisms for subsequent attachment of components

- Moving and transporting is child's play thanks to special travelling units

- Sustainable use of resources: Reuse of individual components

- Process costs reduced by up to 50% over the entire process

readychain® rack - Quickly ready for use

... modular, quick, ready to install

Everything from a single source

The readychain system includes pre-fitted, customised energy chain systems. The "plug and play" solutions are configured, manufactured and delivered according to individual customer specifications. The use of the mounting rack can yield benefits even from as few as five systems per year.

Flexible components

The telescopic supports and braces of the readychain rack allow flexible adaptation to the installation needs on site. Changes in high-volume production can be undertaken easily. By using modular parts, additional components can also be easily attached to the rack.

Sustainable thanks to unlimited reusability

The components of the readychain rack are galvanised and thus designed for a long service life. Each rack can be constructed within a few hours. The individual elements can be reused at any time removing the need to dispose of custom made parts, such as conventional welded transport racks.

Precisely fitting plug and play

All interfaces and attachments are designed in such a way that the installation of the energy chain can be managed quickly and easily.

The complete package includes the matching plugs and connectors, plates, sensor actuator boxes, linear bearings, links to the central lubrication, etc., all reducing the installation time considerably.

Easy transport

The modular system's heavy-duty travelling units shorten transport times and also reduce the amount of handling required during installation.

Previously, forklift trucks or cranes had to be used for in-house transport and positioning of the complete units.

Application example

Minutes instead of days: Complete solution reduces installation time for machining centres

Normally, machine tool manufacturers try to avoid situations where too many different work steps have to be carried out on a system at the same time. A lot of manual work done by different employees does not automatically enhance efficiency; on the contrary, it increases the probability that errors can occur.

By using readychain systems, all four e-chains can be fully installed in half a day. Previously, two employees took one and half weeks for the work on the X-axis of an AERO system and a further week for the energy supply of the Y and Z-axes. This allowed Hartford to save some work steps, reduce process costs and at the same time, greatly improve productivity.

motion - magazine for energy chain systems

Tech up ... Cost down.

In this igus® magazine you will find numerous possibilities and application examples of how you can improve technology and/or reduce costs with ready-to-install energy chain systems.

Tech up, cost down. It's our job.

More products & information

Ready-to-install energy supply systems

Harnessed energy supply systems from a single source: save up to 80% on process costs with our igus readychain offers.

Ready-to-connect drive cables

With around 4,600 harnessed motor, servo, signal and encoder cables, igus is the world's No. 1 for harnessed cables for use in energy chains.

Industrial plug-in connectors

Power connectors, signal connectors and several thousand connector components - this is how igus creates high material availability with short delivery times.

Cable sold by the metre

Cables sold by the metre for moving applications in the energy chain: chainflex meets all requirements for electromagnetic compatibility safety as well as standards and guidelines such as UL, CSA, EAC and many more.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.