Change Language :

New plain bearing products from igus

Yet more tried-and-tested iglidur materials now without PTFE

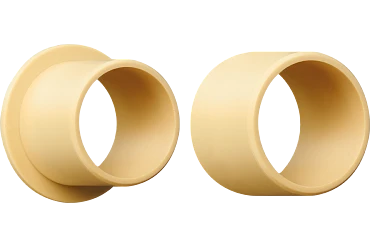

iglidur standards without PTFE

The PTFE-free versions of the bestsellers iglidur G for universal applications and iglidur X and H for high temperature and chemical contact now complement our PTFE-free plain bearing product range.

Cost-effective and extremely wear-resistant under high loads

iglidur W300E multi-component plain bearing

This high-strength 2-component injection-moulded plain bearing is based on the universally applicable material iglidur W300 and is exceptionally strong and durable.

Quick to screw on, cost-effective and sliding

Gliding guide pads from iglidur GLW

The new glide pads are perfect for guiding aluminium or steel rails. They can be flexibly adapted thanks to their shape.

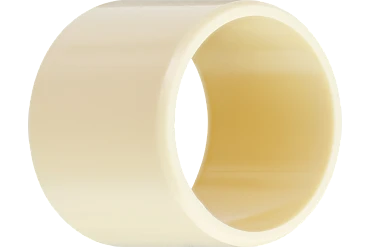

New material for extremely low bearing clearance

iglidur G2

The exceptionally low moisture absorption and thermal expansion combined with high dimensional stability enable very low bearing clearance (G9).

Universal sliding segments for any quantity

iglidur universal sliding segments

The flexible sliding segments made of the wear-resistant heavy-duty material iglidur Q3 enable any bearing diameter from 250mm.

Individually customisable and usable

Stainless steel mesh with iglidur coating

This flexible and robust stainless steel mesh with iglidur coating is customisable and ideal for various industrial applications. Also available as a plate in the dimensions 1,200 x 800mm.

Other new products that may also be of interest to you

For extreme endurance, now PTFE-free

iglidur W300PF

The newly developed material iglidur W300PF offers the performance of the proven endurance runner iglidur W300 - completely without PTFE.

Wear-resistant and flexible

Double flange bearing made of iglidur K230

The new material iglidur K230 offers lower moisture absorption and even more flexibility compared to the clip bearings made of iglidur M250

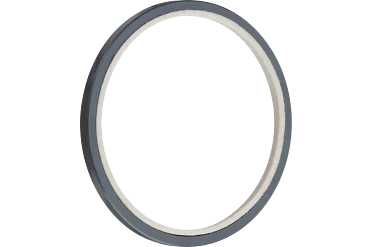

100% protected against dirt

iglidur SG-03

Thanks to the product range addition, the available diameters now include 30, 40, 50, 60 and 70mm.

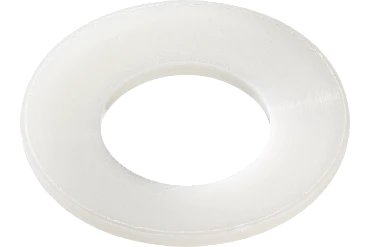

Chemical-resistant, low-cost

iglidur C160 disc springs

With iglidur C160, disc springs are particularly resistant to chemicals and also cost-effective.

The proven endurance runner without PTFE

iglidur JPF

Based on the tried and tested endurance runner material iglidur J, iglidur JPF offers comparable specifications -

without the use of PTFE.

iglidur FPF

For antistatic requirements, without PTFE

The new material iglidur FPF is not only conductive and therefore ideal for applications with ESD requirements,

but also PTFE-free.

iglidur IC-05PF coating powder

The all-rounder with FDA and no PTFE

According to FDA, EU 10/2011 and - now new - without PTFE. With outstanding sliding and wear properties.

Now for all iglidur bearings

Calculate CO2 footprint for each component

CO₂ emissions must be determined and reduced in more and more areas. We support you in this: The CO2 emissions generated during the transport and manufacturing processes of our bearings can now be calculated and displayed for each iglidur plain bearing. This allows you to compare plain bearings and select the one with the lowest carbon footprint for your application.

Made from cost-effective regranulate for high loads

iglidur Q2LW

The regranulate version of the proven heavy-duty plain bearing material iglidur Q2 is perfect for price-sensitive

applications with high loads.

When it needs to be particularly cost-effective

iglidur econ materials

The materials of the econ series, iglidur J4, GLW, P4, PLW210, ALW350, HLW and -new - Q2LW are not only ideal for many applications, but are now also available on the European market in standard dimensions.

Virtually unlimited diameters

iglidur "large bearings"

With the new bearing segments made of iglidur J, plain bearings with large diameters can be realised quickly and easily by means of postforming processes.

igutex TXH - flexible processing all round

High-load composite bearing with homogeneous structure

The new fibre composite material for high loads has a homogeneous layer structure and can therefore be processed

and used on all sides.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.