Change Language :

Sealing concept with felt

Our iglidur and igutex plain bearings with felt seal prevent the ingress of dirt and dust into the bearing position. This protects the shaft and plain bearings from wear and premature failure.

Dirt and dust are heavy loads for plain bearings and shaft. For this reason we have developed an additional safety concept for our self-lubricating iglidur plain bearings: felt seals. Simply placed on the flange of the bearing, they prevent the ingress of dirt, prolonging the time between maintenance intervals and reducing machine downtime.

The innovative felt sealing systems in our iglidur plain bearings and igutex fibre composite bearings

Thanks to the innovative felt sealing system in our iglidur and igutex products, you can dispense with lubrication while keeping dirt and dust safely out of the bearing position. By eliminating complex lubrication systems, you save costs and benefit from the advantages of iglidur and igutex plain bearing materials.

Clean and environmentally friendly

iglidur® bearings are generally insensitive to dirt and dust due to their lubrication-free dry operation. This is due to the fact that dirt does not remain in the bearing position for long in most applications but can trickle through.

In applications with very high dirt loads, however, this effect is no longer sufficient. In these cases, permanent relubrication is often a method to force the dirt permanently out of the bearing point.

Thanks to iglidur plain bearings with felt seal, you can dispense with lubrication and still keep dirt and dust safely out of the bearing position. You can do without expensive lubrication systems and protect the environment.

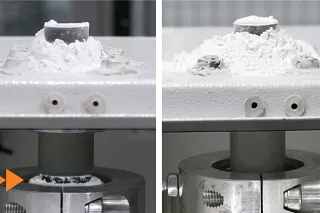

Tested in the igus test laboratory

Test medium: talcum

Speed 33rpm

Left:

- Plain bearing without sealing concept

- Throughput of the test medium after 30 minutes

Right:

- Plain bearing with SG03 sealing concept

- No throughput of the test medium after 24 hours

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.