Change Language :

Application locations for bearings and energy chains in buses

Finding the right product for every installation position and requirement

When selecting the right bearings, linear guides or energy chains for buses, numerous requirements must be taken into account, including friction, wear, vibrations, limited installation space, humidity and dirt. Whether in a city bus or coach, the number of moving parts is high.

On this page, we would like to show you which bearing materials, linear guide systems and energy chain series are best for the respective applications.

Passenger seats

Plain bearings are often used in sheet metal for seat adjustments. Our clip bearings are easy to install and simply calibrate themselves during the e-coating process. For horizontal adjustment, our small energy chains and robust drylin W-linear guides are the right choice. Thanks to the absence of external lubricants, no dirt sticks to the bearing points, wear is minimised and maintenance is eliminated.

Discover application locations in vehicle seats

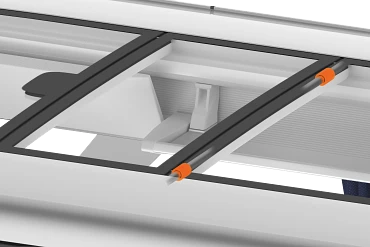

Roof hatches

Environmental conditions such as dirt, dust and moisture have a negative impact on the service life of plain bearings in roof hatches. Self-lubricating plastic bearings are advantageous here, as they are dirt-resistant and corrosion-free, thus ensuring a longer service life and reliable function.

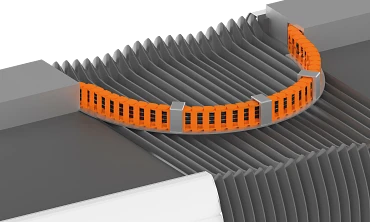

Gangway on articulated buses

Cables that run between the front and rear of articulated buses are constantly in motion during the journey. Special guide systems in or on the vehicle ensure that they do not kink or break. For roof systems on e-buses, the large packages of high-voltage, battery and other cables, energy chains are needed that withstand high loads, are weather-resistant and are as lightweight as possible.

Suitable energy chain:

E4/light 1640 e-chain

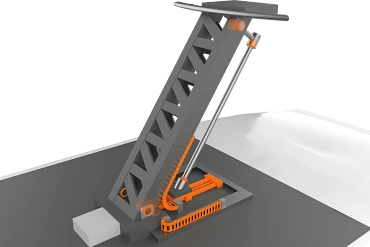

Current collector, pantograph

Our plain bearings, made from non-conductive high-performance polymers, are ideal as insulating components for bearing points on pantographs. They are also unaffected by the corrosive effects of the weather. The same applies to our linear axes in combination with e-chains, which guide the cables safely and ensure reliable movement.

Wheelchair ramp

Bearings used in steps and wheelchair ramps need to be resistant to moisture, corrosion, pressure and edge loads. For electrically extendable models, manufacturers rely on our lubrication and rust-free lead screw technology and compact e-chains, which protect the cables from wear even in the tightest installation spaces.

Pivot-and-slide doors

There is little space available for cables in entrance systems. To prevent premature wear, particularly flexible, hard-wearing cables and compact energy supply systems are required. At the pivot and connection points of the door leaves, spherical bearings offer the advantage of compensating for misalignment during installation, reducing the load and increasing the service life of the bearings. Corrosion and dirt resistance are also important here.

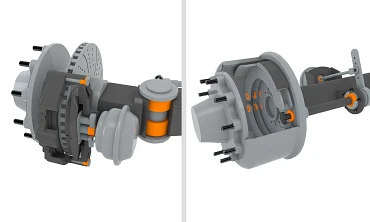

Axes and braking systems

Plain bearings used in axes must be able to withstand high edge loads, should be dirt and oil-resistant and ideally have vibration-damping specifications. The same applies for use in brake systems, where high temperatures must not lead to any loss of function.

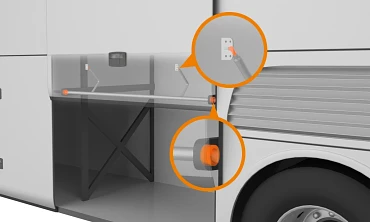

Luggage compartment flaps

Our cost-effective plain and (in the gas struts) angled spherical bearings are suitable for all-round use at bearing points on the flaps of luggage compartments. Compared to metal, the plastic material scores points for its quiet running, vibration-damping specification and freedom from corrosion, lubrication and maintenance.

Wing mirrors

Due to their exposed position, bearings in the adjustment points of side mirrors are exposed to moisture, dust and dirt. Dry-operating plastic bearings are a great advantage to prevent the lubricant from being washed out and contaminated and to avoid inadequate lubrication. A material with low moisture absorption is ideal here.

Sunblind

In the articulated arms and roller bearings of sunblinds, it is important that the bearings are as light as possible, run quietly and are ideally maintenance-free. Low fogging is also a safety-relevant factor, as materials that emit gas have a negative effect on the driver's vision and health.

Online trade show stand and roadshows

Consulting

I look forward to answering your questions

igus® Singapore Pte Ltd. Headquarter ASEAN+65 6487 1411Write e-mail

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.