Change Language :

Linear axes with lead screw drive

What you will find on this page:

Our spindle axes at a glance

Here you will find an overview of our linear axis product portfolio with spindle drive. Whether with round shafts or linear rails - you will find the right spindle unit here.

Advantages of spindle axes

When a cost-effective, ready-to-install solution is required, spindle axes are often the first choice. Here you can see what other advantages the linear drive with the aid of a spindle has over other systems:

Precise positioning

By converting the rotary motion from the spindle directly into a linear motion, very accurate and repeatable positioning is achieved. This is crucial in applications with tight tolerances and high precision.

Compact design

Spindle axes are also available in particularly small versions. Thanks to their compact design, they are perfect for all applications where only a small installation space is available. Discover our complete drylin® miniature series.

High load capacity

Spindle drives in linear modules are able to carry and move very high loads. In contrast to flexible toothed belts, for example, spindle axes can ensure efficient power transmission due to their low rigidity.

Low-friction movement

Linear modules with spindle drive are particularly low-friction. The constant, precise movement of the spindle drive minimises friction and therefore also wear on the components. This ensures a longer service life for the entire spindle axis.

Structure of a lead screw axis

A lead screw axis contains several complex components that must fit together perfectly.A precise structure plays a key role in the performance and accuracy of the linear axis.Here you can see the most important components at a glance.

Different materials within the axis

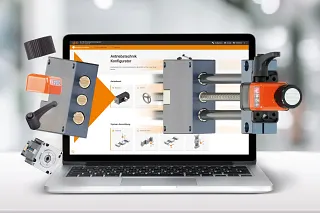

drive technology configurator

Customised spindle axes according to your wishes

With the online configurator for drive technology, you can enter your requirements and receive linear drives with spindle, toothed belt or rack and pinion drive, which you can configure according to your needs. Motors, motor controls and other accessories for your linear drives can also be ordered directly.

- Quick and easy configuration

- Optional accessories

- Detailed parts list

- Fast delivery*

Application examples with lead screw axes

Free sample & white paper

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 8:30am - 5.30 pm.

Online:

24h

WhatsApp-Service:

Monday - Friday: 8:30am - 5.30 pm.